The dawn of a new space age is upon us, marked by significant milestones and technological advancements. As humanity ventures further into space, the role of in-space manufacturing emerges as a pivotal factor in shaping the future of the global space economy.

This transformative technology promises to redefine our capabilities in space exploration, satellite deployment, and beyond. In this comprehensive exploration, we look into the multifaceted impacts of in-space manufacturing on the space economy, dissecting its potential to revolutionize our approach to space exploration and commercialization.

Economic Catalyst for Space Exploration

In-space manufacturing stands as a game-changer in the economics of space exploration. By enabling the production of materials with unique properties unattainable on Earth, it opens the door to an exclusive market for space-made products.

These products, boasting superior qualities, create a unique selling proposition, driving economic growth and incentivizing further space exploration.

- Unique material properties developed in microgravity

- Creation of a distinctive market for space-manufactured products

Synergy with Emerging Space Technologies

The advent of in-space manufacturing synergizes remarkably with recent innovations like reusable rockets and commercial space stations. This synergy amplifies the economic benefits of space exploration, reducing costs and broadening access to space, thus making it a more lucrative and sustainable venture.

- Integration with reusable rocket technology

- Complementing the growth of small satellites and commercial space platforms

Transformative Satellite Design and Deployment

Traditional satellite design is heavily constrained by the limitations of launch vehicles. In-space manufacturing liberates these designs, allowing for the assembly of satellites in orbit.

This freedom enables more efficient and functional designs, no longer bound by the rigors of terrestrial launch conditions.

- Designing satellites for efficiency rather than launch compatibility

- Reduced constraints from launch vehicle specifications

Advancements in Satellite Capabilities

The ability to manufacture and assemble satellites in orbit leads to enhanced capabilities and functionalities. Larger satellites become more cost-effective to build, and smaller satellites gain increased power and functionality, akin to their larger counterparts.

This evolution in satellite technology marks a significant leap forward in space operations.

- Enabling smaller satellites with enhanced capabilities

- Cost reduction in the construction of larger satellites

Revolutionizing Launch Dynamics

In-space manufacturing fundamentally disrupts the current paradigms of space launches. By building and assembling parts in orbit, the need for large, expensive rockets diminishes.

This shift not only reduces costs but also paves the way for more frequent and diverse launches, thereby enhancing overall space accessibility.

- Reducing reliance on large launch vehicles

- Lowering the cost and increasing the frequency of space launches

Expanding the Launch Market

The newfound capabilities in space manufacturing expand the launch market significantly. With the ability to launch smaller and more affordable rockets, a wider range of satellites can be deployed, catering to various needs and applications.

This expansion fosters a more dynamic and competitive launch industry.

- Facilitating the launch of a diverse array of satellite sizes and types

- Promoting competition and growth in the launch market

Redefining Spacecraft Design Standards

The introduction of in-space manufacturing marks a significant milestone in spacecraft design. Traditional approaches, often limited by terrestrial manufacturing constraints, are being reevaluated.

This shift allows for more ambitious and complex designs, tailored to the unique conditions of space rather than the limitations of Earth-bound manufacturing processes.

- Design flexibility and complexity previously unattainable

- Customized designs optimized for space conditions

Enhanced Longevity and Maintenance

In-space manufacturing and assembly offer substantial benefits in terms of spacecraft longevity and maintenance. The ability to repair, upgrade, and maintain spacecraft in orbit can dramatically extend their operational lifespan, resulting in significant cost savings and increased efficiency in space missions.

- Extended operational life of spacecraft through in-orbit maintenance

- Cost savings from reduced need for frequent replacements

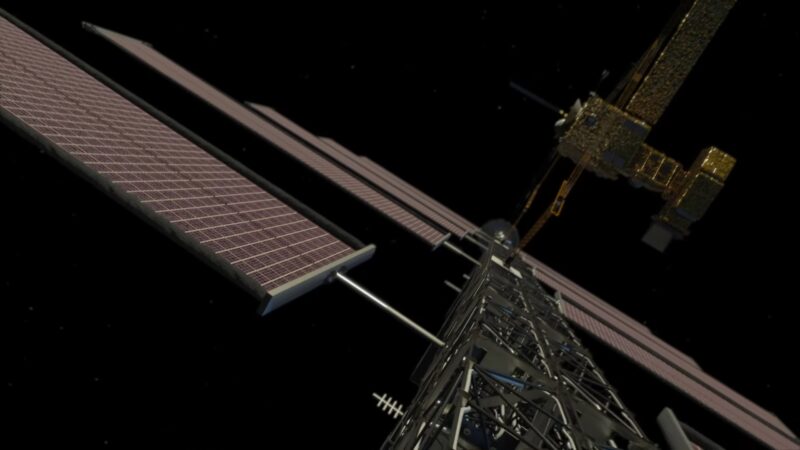

Archinaut One: Pioneering In-Space Manufacturing

Archinaut One, a project initiated by NASA, represents a groundbreaking step in the field of in-space manufacturing. This mission aims to demonstrate the practicality and efficiency of manufacturing and assembling parts of a satellite in orbit.

A successful mission will not only validate the technology but also showcase its potential to revolutionize space exploration and commercialization.

- Demonstrating the feasibility of in-space manufacturing and assembly

- Potential to revolutionize satellite deployment and space exploration

Expanding Capabilities in Space

The success of Archinaut One could lead to unprecedented advancements in space technology. By proving the ability to manufacture and assemble complex structures in space, this mission could pave the way for more ambitious projects, including the construction of large-scale space structures and platforms, previously deemed unfeasible due to launch constraints.

- Enabling the construction of large and complex space structures

- Overcoming limitations imposed by terrestrial manufacturing and launch constraints

Building Unprecedented Space Structures

In-space manufacturing unlocks the potential to build structures in space that were previously impossible. This includes large-scale projects like telescopes and space stations, which can now be constructed in orbit, free from the size and weight limitations of earthbound manufacturing and launch processes.

- Construction of large-scale telescopes and space stations

- Overcoming size and weight limitations of traditional space structures

Advancing Scientific and Commercial Endeavors

The ability to construct such ambitious projects in space opens new frontiers for scientific research and commercial activities. Large telescopes can provide deeper insights into our universe, while space stations can serve as platforms for research, tourism, or even as manufacturing hubs, further fueling the growth of the space economy.

- Enhanced capabilities for scientific research and observation

- New opportunities for commercial activities in space

FAQ

What are the environmental impacts of in-space manufacturing?

- In-space manufacturing could reduce Earth’s environmental burden by shifting some production processes to space.

- Research is ongoing to understand the potential ecological footprint of manufacturing activities in space.

How does in-space manufacturing influence space law and governance?

- It raises questions about resource usage and ownership in space, necessitating updates in international space law.

- Regulations and policies are being developed to govern commercial activities and resource utilization in space.

What are the potential risks associated with in-space manufacturing?

- Technical challenges and the risk of space debris are primary concerns.

- Ensuring operational safety and mitigating collision risks are critical areas of focus.

Can in-space manufacturing contribute to deep-space exploration?

- Yes, it can enable the construction of spacecraft and habitats for missions to Mars and beyond.

- Manufacturing in space reduces the need for transporting materials from Earth, making deep space missions more feasible.

What role do international collaborations play in in-space manufacturing?

- International partnerships are vital for sharing technology, costs, and expertise.

- Collaborations can accelerate technological advancements and foster a global approach to space exploration.

How will in-space manufacturing affect the workforce?

- It may create new job opportunities in space-related industries and require new skills and training programs.

- The shift could also influence the job market on Earth, with an emphasis on robotics, AI, and space technology.

Are there ethical considerations in in-space manufacturing?

- Ethical concerns include equitable resource distribution and the potential militarization of space.

- Ongoing discussions aim to ensure that space activities benefit humanity as a whole.

Final Words

In-space manufacturing is a beacon of innovation, promising to transform how we approach space exploration and the global space economy. As we stand on the cusp of this new era, it’s essential to navigate these uncharted territories with foresight and responsibility, ensuring that our journey into space benefits all of humanity.